this presentation is based on The Kanban Guide (2020) by Daniel S. Vacanti

available from kanbanguides.org under CC BY-SA 4.0

or download directly from here

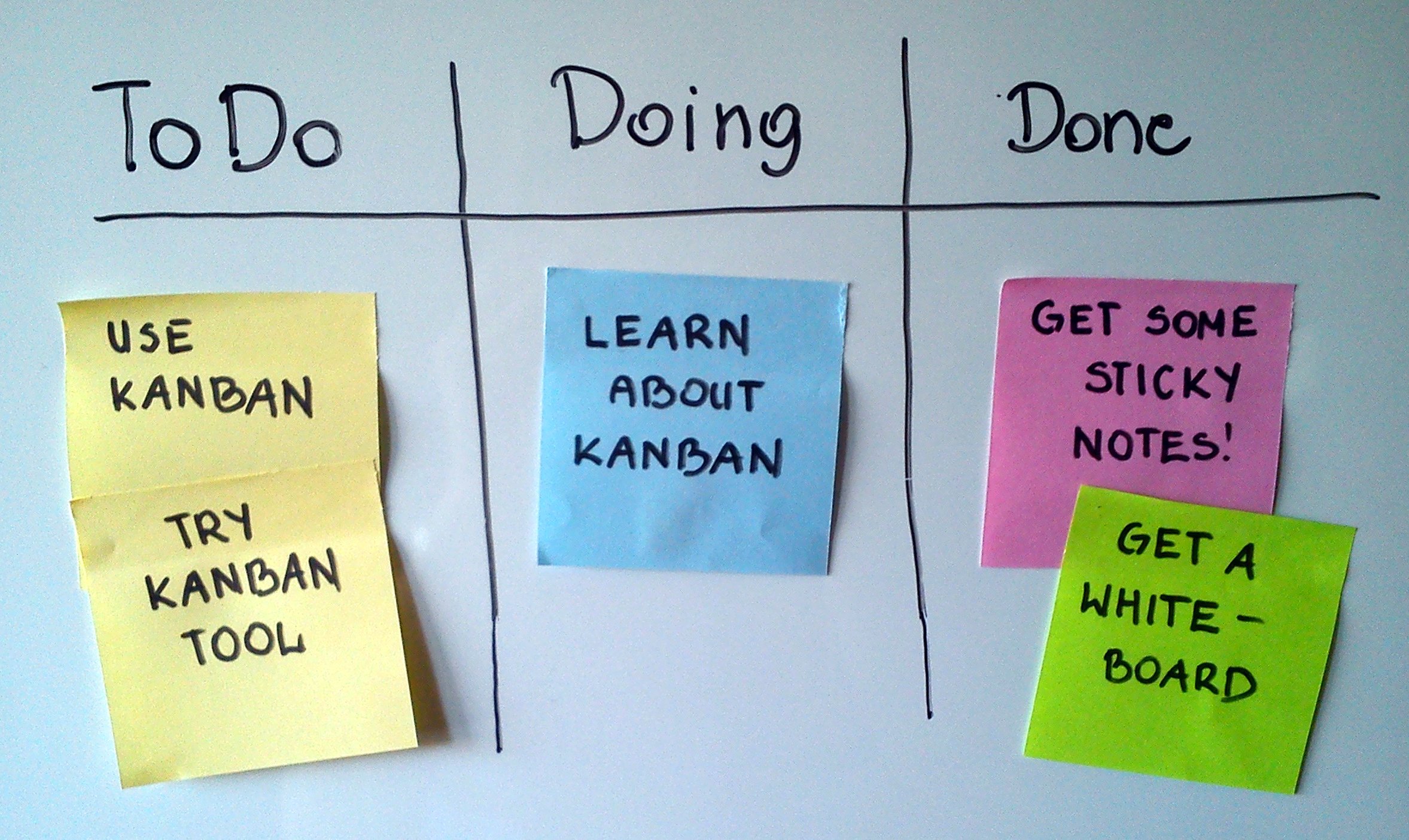

what is kanban?

Kanban is a strategy for optimizing the flow of value through a process that uses a visual, pull-based system

The word “kanban” roughly means board in Japanese (signboard or billboard, actually).

principles of kanban

- defining and visualizing a workflow

- actively managing items in a workflow

- improving a workflow

These Kanban practices are collectively called a Kanban system. Those who participate in the value delivery of a Kanban system are called Kanban system members.

how does kanban work?

- notes move from left to right

- order denote priority

- allways process the right- and topmost one to finish it ASAP

- tool-dependent but a note can indicate:

- who’s responsible

- how much effort to do it

- etc.

kanban for job hunting

Kanban is a general technique, you can use it for household chores, for job applications (e.g., backlog, application sent, interview, done, declined). A whiteboard can be used or there a many different software for the task. Some general examples are: - Trello (https://trello.com/), - free and paid plans - Taiga (https://taiga.io/). - open source, self-hosted, cloud based free and paid plans - WeKan (https://wekan.github.io/) - open source, self-hosted

defining and visualizing the workflow

- definition of workflow (DoW)

- the visualization of the DoW is called a Kanban board

- states (columns)

- conditions when to move an item between columns

- a definition of the individual units of value that are moving through

the workflow

- referred to as work items (or items)

defining and visualizing the workflow

- a definition for when work items are started and finished within the

workflow

- a workflow may have more than one started or finished points

defining and visualizing the workflow

- one or more defined states between the started to finished

- item between start and finish point are considered work in progress (WIP)

- a definition of how WIP will be controlled from started to finished

- explicit policies about how work items can flow through each state

Service Level Expectation

- a service level expectation (SLE)

- which is a forecast of how long it should take a work item to flow from started to finished

- the SLE itself has two parts: a period of elapsed time and a

probability associated with that period

- e.g., 85% of work items will be finished in eight days or less

Service Level Expectation

- the SLE should be based on historical cycle time

- and once calculated, should be visualized on the Kanban board

- if historical cycle time data does not exist, a best guess will do until there is enough historical data

improving the Workflow

- it is common practice to review the DoW from time to time to discuss

and implement any changes needed

- e.g., need a new column for a new state

- not necessary to wait for a formal meeting at a regular cadence to make these changes

kanban measures

- WIP: number of work items started but not finished

- throughput: number of work items finished per unit of time

- Note the measurement of throughput is the exact count of work items

- work item age: elapsed time from when a work item started

- cycle time: time between when a work item started and finished

Visualizing these metrics using charts is recommended. It does not matter what kind of charts are used as long as they enable a shared understanding of the Kanban system’s current health and performance.

Toyota’s six rules (Wikipedia contributors, 2024)

- Each process issues requests (kanban) to its suppliers when it consumes its supplies.

- Each process produces according to the quantity and sequence of incoming requests.

- No items are made or transported without a request.

- The request associated with an item is always attached to it.

- Processes must not send out defective items, to ensure that the finished products will be defect-free.

- Limiting the number of pending requests makes the process more sensitive and reveals inefficiencies.

kanban in software development

Kanban is widespread in software development. The major code hosting solutions (GitHub, GitLab, Bitbucket, Gitea) all have some board functionalities.

scrumban

SCRUM and kanBAN can coexist

Scrum contributes to scrumban:

- sprints

- daily standups

- retrospectives

Kanban contributes to scrumban:

- board

- cards

- work-in-progress limits

references

Wikipedia contributors. (2024). Kanban — Wikipedia, the free encyclopedia. https://en.wikipedia.org/w/index.php?title=Kanban&oldid=1239509091.