Kanban

Gergő Pintér, PhD

gergo.pinter@uni-corvinus.hu

this presentation is based on The Kanban Guide (2020) by Daniel S. Vacanti

available from kanbanguides.org under CC BY-SA 4.0

or download directly from here

what is kanban?

Kanban is a strategy for optimizing the flow of value through a process that uses a visual, pull-based system

principles of kanban

- defining and visualizing a workflow

- actively managing items in a workflow

- improving a workflow

how does kanban work?

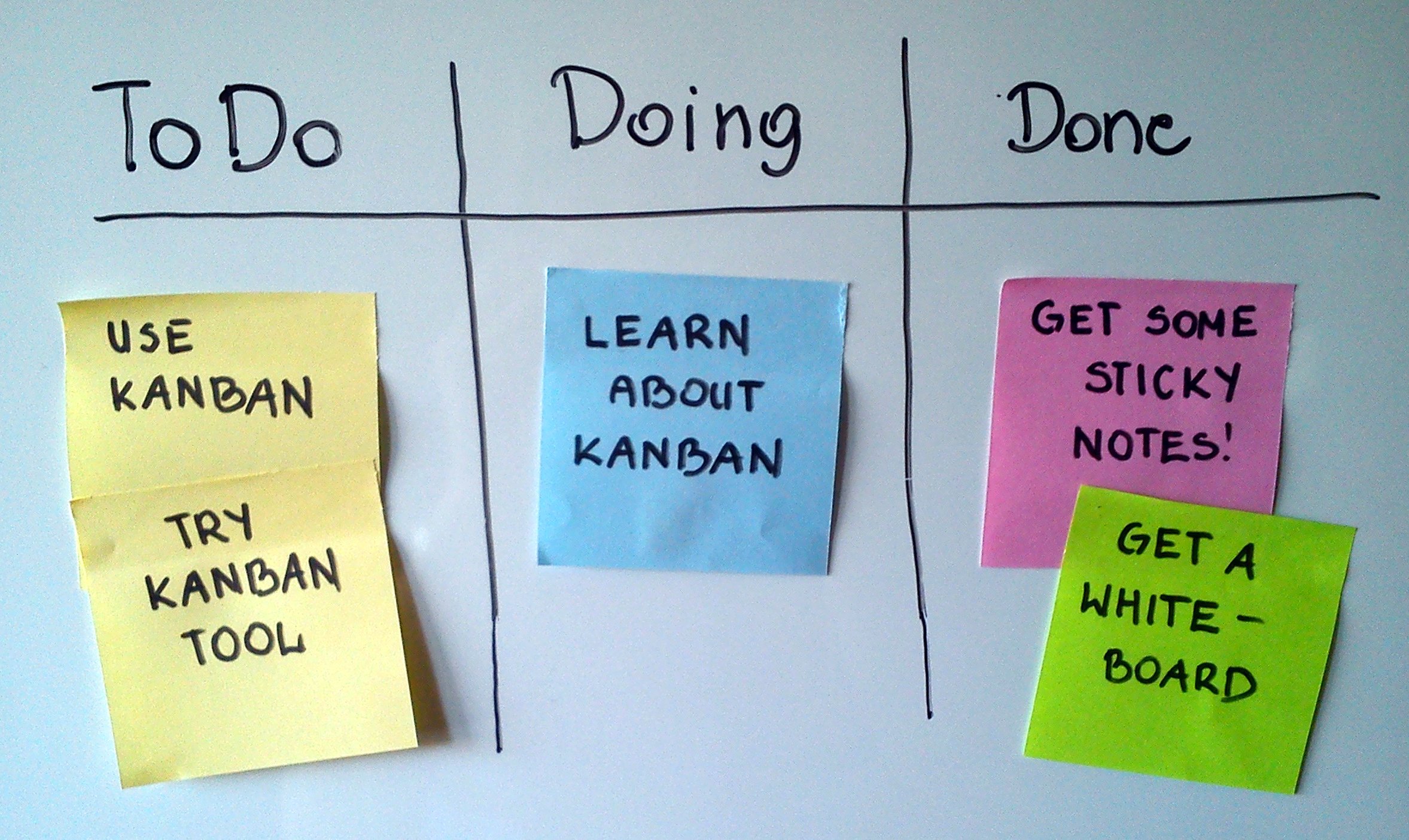

by Jeff Lasovski | CC BY-SA 3.0

- notes move from left to right

- order denote priority

- allways process the right- and topmost one to finish it ASAP

- tool-dependent but a note can indicate:

- who’s responsible

- how much effort to do it

- etc.

kanban for job hunting

defining and visualizing the workflow

- definition of workflow (DoW)

- the visualization of the DoW is called a Kanban board

- states (columns)

- conditions when to move an item between columns

- a definition of the individual units of value that are moving

through the workflow

- referred to as work items (or items)

defining and visualizing the workflow

- a definition for when work items are started and finished within the

workflow

- a workflow may have more than one started or finished points

defining and visualizing the workflow

- one or more defined states between the started to finished

- item between start and finish point are considered work in progress (WIP)

- a definition of how WIP will be controlled from started to finished

- explicit policies about how work items can flow through each state

Service Level Expectation

- a service level expectation (SLE)

- which is a forecast of how long it should take a work item to flow from started to finished

- the SLE itself has two parts: a period of elapsed time and a

probability associated with that period

- e.g., 85% of work items will be finished in eight days or less

Service Level Expectation

- the SLE should be based on historical cycle time

- and once calculated, should be visualized on the Kanban board

- if historical cycle time data does not exist, a best guess will do until there is enough historical data

improving the Workflow

- it is common practice to review the DoW from time to time to discuss

and implement any changes needed

- e.g., need a new column for a new state

- not necessary to wait for a formal meeting at a regular cadence to make these changes

kanban measures

- WIP: number of work items started but not finished

- throughput: number of work items finished per unit of time

- Note the measurement of throughput is the exact count of work items

- work item age: elapsed time from when a work item started

- cycle time: time between when a work item started and finished

Toyota’s six rules [1]

- Each process issues requests (kanban) to its suppliers when it consumes its supplies.

- Each process produces according to the quantity and sequence of incoming requests.

- No items are made or transported without a request.

- The request associated with an item is always attached to it.

- Processes must not send out defective items, to ensure that the finished products will be defect-free.

- Limiting the number of pending requests makes the process more sensitive and reveals inefficiencies.

kanban in software development

scrumban

SCRUM and kanBAN can coexist

Scrum contributes to scrumban:

- sprints

- daily standups

- retrospectives

Kanban contributes to scrumban:

- board

- cards

- work-in-progress limits

references

[1]

Wikipedia contributors, “Kanban —

Wikipedia, the free encyclopedia.” https://en.wikipedia.org/w/index.php?title=Kanban&oldid=1239509091,

2024.